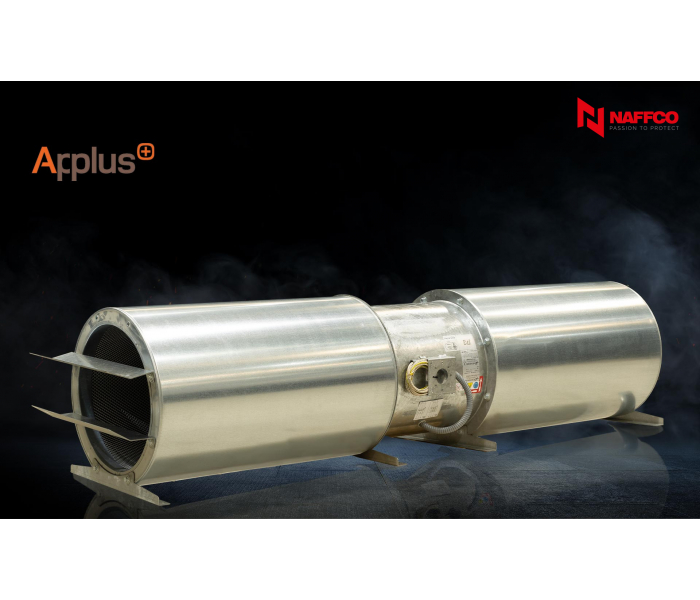

Axial Jet Fans

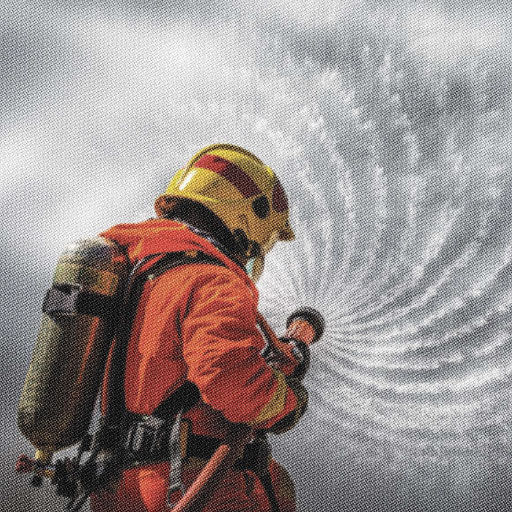

Induction ventilation systems, 300/400°C for 120 minutes.

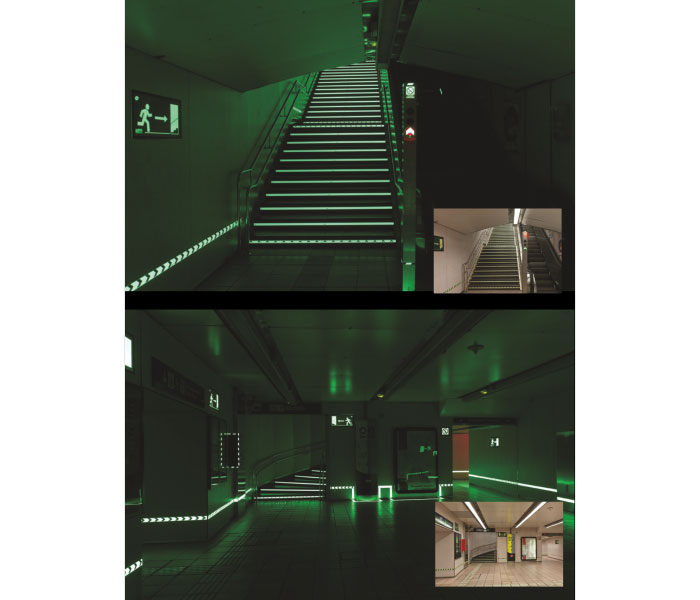

Forced ventilation for carparks to remove the smoke & polluted gasses.

Ductless, offering a series of advantages: economical and huge saving in installation.

Multiple european laboratories, BSI KITEMARK & APPLUS.

|

SIZE RANGE |

MOTOR (KW) |

THRUST |

|

310-1600 |

Two speed Motor |

100N to 1400N |

APPLICATIONS AND ADVANTAGES

Impulse fans JP-DUCT are used in the forced ventilation of car parks, to remove the most common pollutions (ex. CO) and in case of emergency (fire) it activates to prevent and restrict the damages to people and objects: creating escape routes from toxic smokes, preventing the propagation in the adjacent zones etc.

Impulse fan JP-DUCT has the main characteristic to be ductless, offering a series of advantages as:

- Remarkable saving in times and costs of installation.

- Saving in running costs, possibility to ventilate or extract only specific areas of the garage, where it is effectively required.

- Ease of removal with consequent lower costs of maintenance or displacement of the plant.

JP-DUCT have been designed and manufactured in accordance with the new European Directive EN 12101-3 obtaining the certification by an independent certification body.

This line is suitable to S1 service (continuous operation) at the temperature of 40°C and S2 service in case of emergency (fire) at the temperature of:

- 200°C for 120 minutes (F200).

- 300°C for 120 minutes (F300).

- 400°C for 120 minutes (F400).

The motion of double operation is exactly translated by the term “dual purpose” introduced in this case by Directive EN 12101-3.

RANGE

This line consists of 3 sizes, impeller diameter: from 315 mm to 400 mm

Motors are 2 poles single speed, 2/4 poles double polarity tapped winding.

Available versions:

- Uni - directional (JP-DUCT/U)

- Reversible airflow (JP-DUCT/R).

- Standard for operation S1 up to +40°C - Smoke exhaust operation S2

- 200°C/120’ (F200) certified EN 12101-3.

- 300°C/120’ (F300) certified EN 12101-3.

- 400°C/120’ (F400) certified EN 12101-3.

CONSTRUCTION

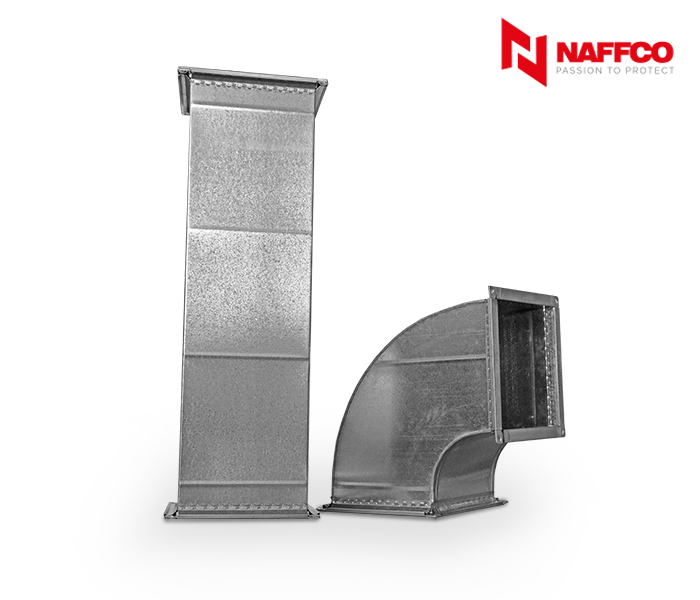

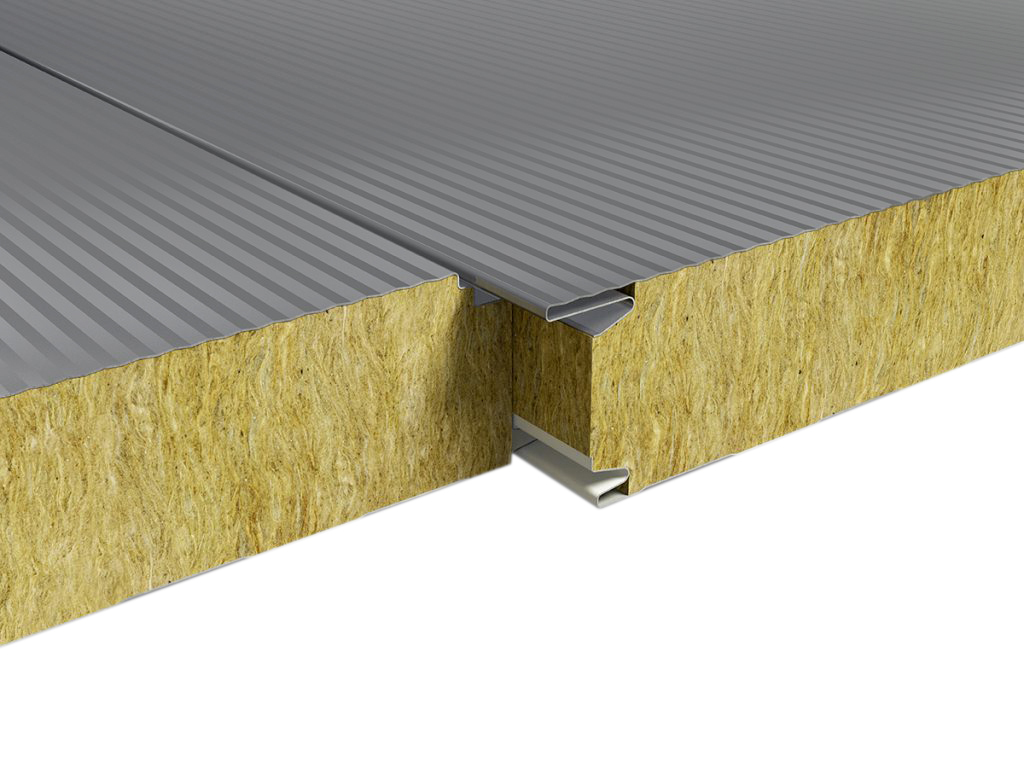

- Casing in metal sheet protected against the atmospheric agents.

- High efficiency impeller in die cast aluminum alloy with airfoil blades and variable pitch angle in still position. Balancing according to UNI ISO 21940-11.

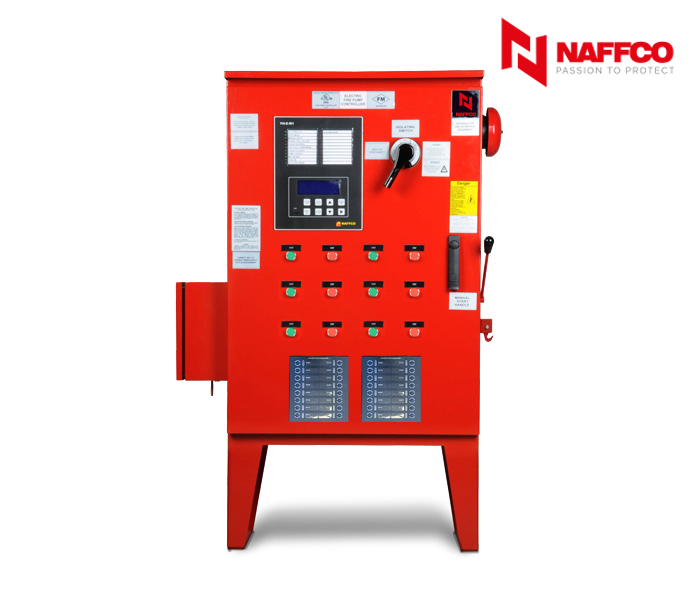

- Asynchronous three phase electrical motor, IP 55, mounting type B3, construction according to IEC/EEC directives, suitable and certified to operate in S1 service (continuous running) up to the maximum temperature of 40°C and S2 service in case of fire emergency for 200°C for 120 minutes or 300°C for 120' or 400°C for 120'.

- Arrangement 4 (impeller directly coupled to the motor shaft)

- N.2 cylindrical silencers in galvanized steel sheet directly flanged to the fan.

- Ceiling fixing system.

- Inlet protection grid and outlet deflector (JP-DUCT/U) or n.2 deflectors for reversible (JP-DUCT/R).

TECHICAL SPECIFICATIONS

- Conveyed air: clean, not abrasive.

- Voltage and frequency:

- Three-phase (T) 400V/50 Hz.

ON REQUEST

- Inlet cone.

- Service switch wired.

- External terminal box wired.