Bifurcated Fans

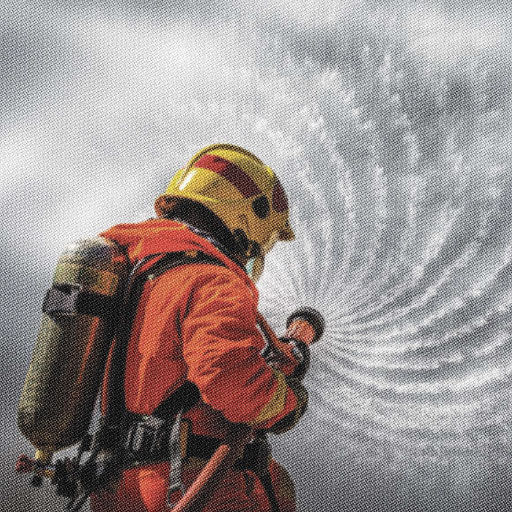

Smoke extraction in case of fire, 300/400°C for 120 minutes.

- Smoke extraction

- Pressurization

- Industrial ventilation & explosion proof application

Multiple european laboratories, BSI KITEMARK, APPLUS.

|

SIZE RANGE (MM) |

MOTOR (KW) |

CAPACITY (LPS) |

|

500-1000 |

0.55-15 KW |

22,500 LPS |

ADVANTAGES

DUCT-BFC are used to exhaust large amounts of hot or dumpy or greasy smoke (up to 150°C), thanks to the position of the motor housed in a protection hollow inside the fan casing.

INSTALLATION

The airflow is only B type (from impeller to motor) and installation is horizontal or vertical. When the fan is installed in horizontal position and water or condensation is expected, the fan shall be rotated in a way to prevent the hollow to hold back liquids.

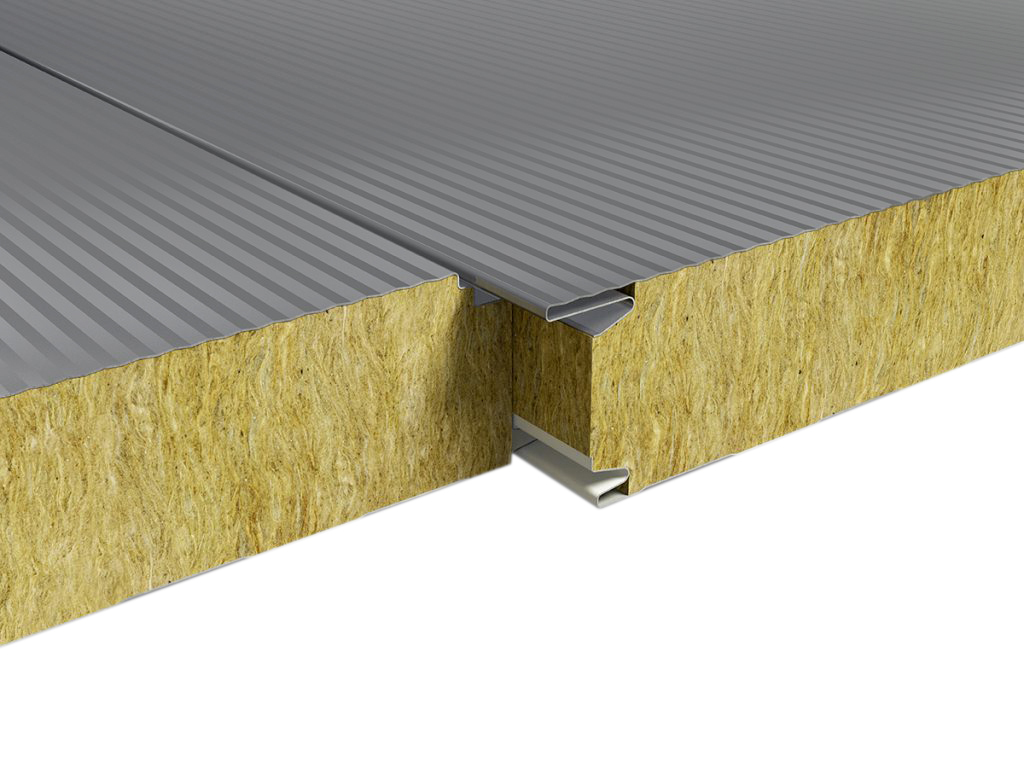

CONSTRUCTION

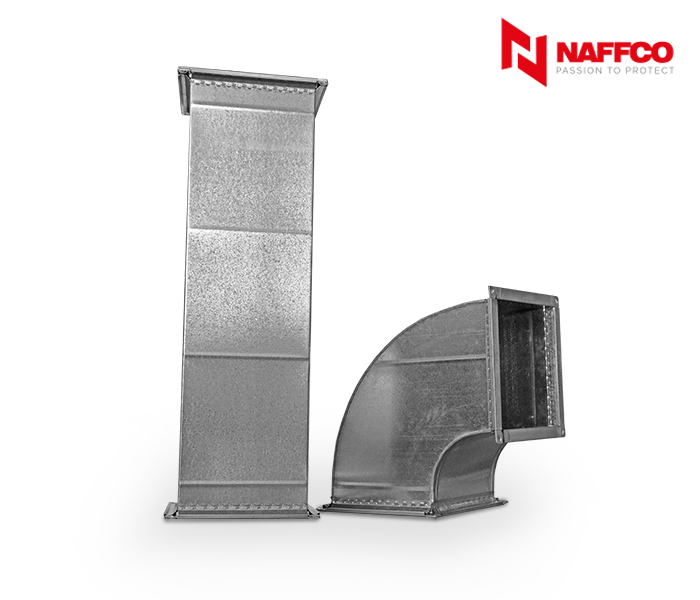

- Casing in hot dip galvanized steel sheet. Flanges according to UNI EN ISO 13351/Tab.1.

- High efficiency impeller with airfoil blades in die cast aluminum alloy, variable pitch angle in still position, hub in die cast aluminum alloy. Balancing according to UNI ISO 21940-11.

- Alternate current asynchronous electric motor, protection IP 55 insulation class F, efficiency EFF.2, S1 service, mounting type B3, construction according to specific directives IEC / EEC (UNEL-MEC).

- Execution 4 (impeller directly coupled to the motor shaft).

DUCT- BFC

- Conveyed air: clean or slightly dusty or greasy, not abrasive.

- The temperature of conveyed air: -20°C / +150°C.

- Voltage: Three-phase version (T) 400V – 50Hz.

- Airflow type B from the impeller to motor (FGM).

ACCESSORIES

- Inlet bell mouth (IN-DU).

- Silencers (SIL-DU).

- Flat protection guard (FPG-DU) (necessary in free inlet or outlet applications).

- Flexible connection (FC-DU).

- AV mounts (AV).

- Counter flange (CF-DU).

- Fixing feet (FF-DU).

ON REQUEST

- Performance differing from standard.

- Versions with casings in stainless steel.

|

Catalog |