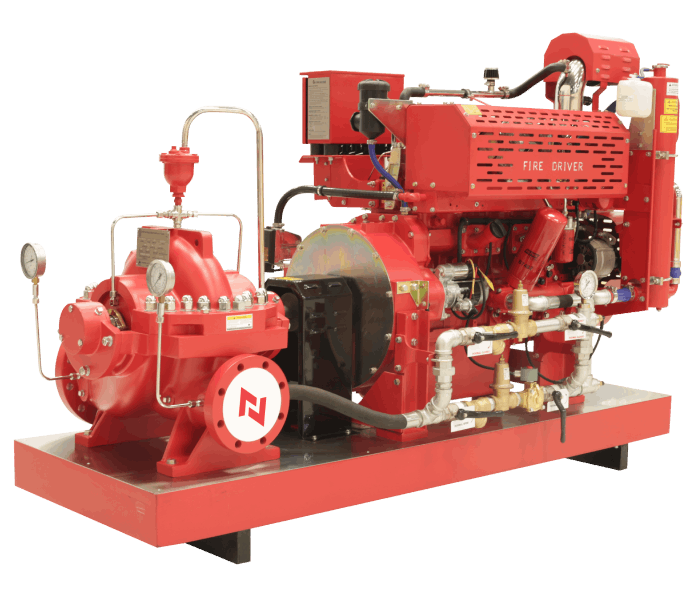

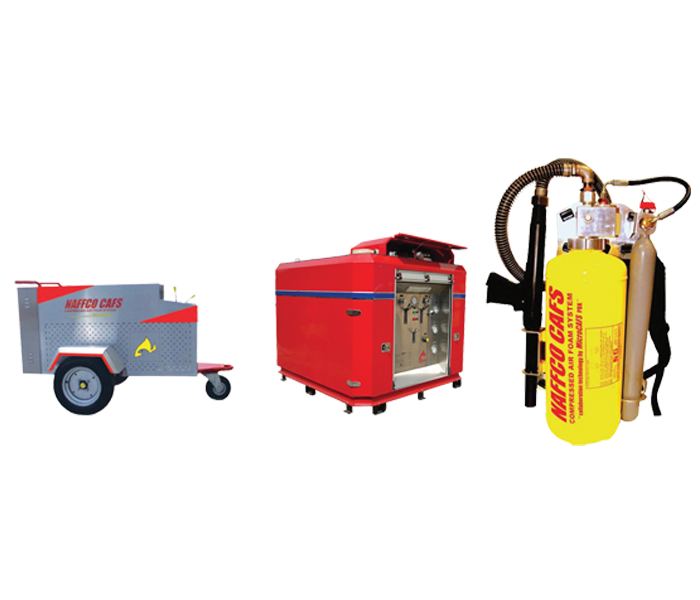

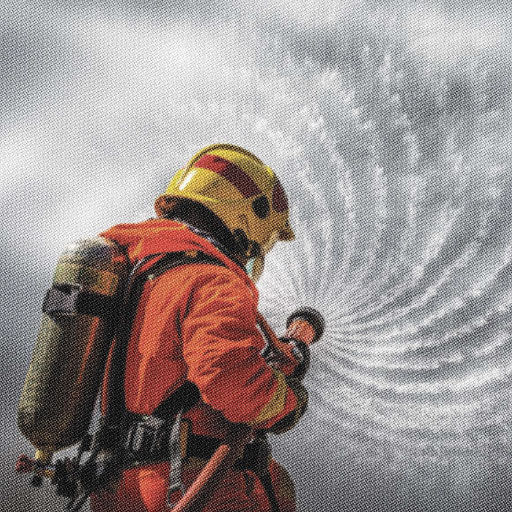

Foam Pump Skid

NAFFCO Balanced Pressure or In-line Balanced Pressure Foam Proportioning Pump Skids are designed as per NFPA 11 to precisely proportion the foam concentrate into the water stream.The systems function over a range of flow and pressures.

The Balanced Pressure or In-line Balanced Pressure Pump Proportioning System functions by maintaining an equal pressure in the foam concentrate inlet and water inlets to the proportioner, which allows the proportioner to be used over a wide range of pressure and flow.

The system consists of a foam pump, a diaphragm operated pressure balancing valve, and all the required piping valves and fittings assembled on a common steel base. NAFFCO also offers the deluge valve and the atmospheric storage tank as an option, on the pump skid as per request. The skid units are available in different proportioner sizes ranging from 2 ½" to 8".

NAFFCO FOAM PUMP

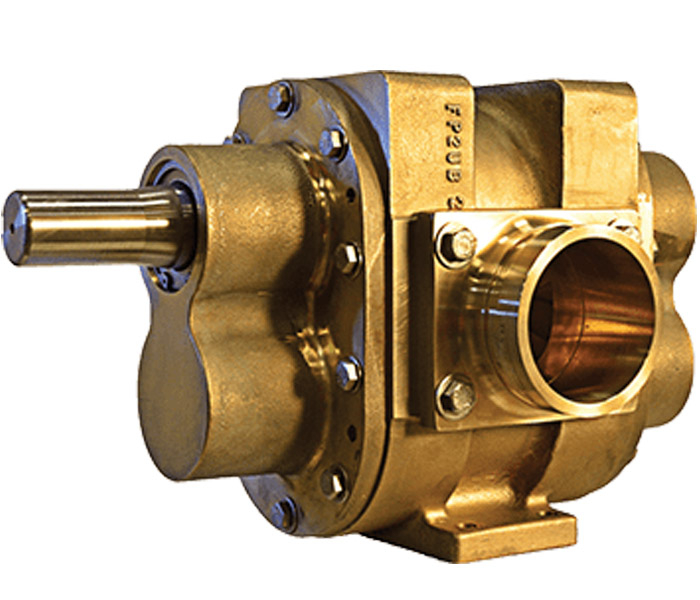

Foam Pump is specialized non-corrosive construction pumps used for Fire Protection, especially for Fire-fighting foam concentrate pumping &Water mist pumping applications. These pumps can also be used for Stationary or mobile systems applications.

NAFFCO Foam pump have 255 Duplex Stainless steel shafts to withstand seawater flush and any brand foam concentrate. Only 1 shaft seal is permitted and shaft seal shall be capable of dry operation for 10 minutes. Shaft seal shall be simple to repair and replace in the field.

Shaft seal materials are 316 stainless casing with double PTFE lips that allow for hydro test pressure to 350 psig without leakage. Pump rotor shall be spur gear design using corrosion resistant materials. Made from admiralty bronze alloy and composite materials that provide no tooth to tooth wear and no corrosion. Foam pump connections shall be Groove, NPT or ANSI flange. Pump connections and end covers shall use O-ring seals for leak free operation and simple field replacement.

- Compact design.

- Major components are UL Listed.

- Can add in options like deluge valve and concentrate tank on the skid if required.

- All foam concentrate valves, pipe and fittings are of stainless steel or brass material for compatibility with all types of foam concentrates

- Foam Concentrate tank can be of GRP or Stainless Steel material or Polyethylene

- Pump skid supplied with manual override capabilities.

- A bypass arrangement is provided for the system to function in the event of malfunctioning of pressure balancing diaphragm valve.

NAFFCO Balanced Pressure or In-line Balanced Pressure Foam Proportioning Pump Skids are designed as per NFPA 11 and as per customer requirement. Below are the NAFFCO UL Listed foam concentrate pump flow range.

|

Model |

NF-FP-30 |

NF-FP-50 |

NF-FP-75 |

NF-FP-101 |

NF-FP-151 |

|||||

|

RPM |

1500 |

1800 |

1500 |

1800 |

1500 |

1800 |

1500 |

1800 |

1500 |

1800 |

|

Flow GPM |

24-36 |

40-55 |

40-56 |

57-72 |

65-90 |

90-115 |

88-119 |

121-152 |

107-140 |

152-185 |

|

Pressure psi |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

|

Port Size |

1x1 |

1x1 |

1.5x1.5 |

1.5x1.5 |

1.5x1.5 |

1.5x1.5 |

2x2 |

2x2 |

2x2 |

2x2 |

|

Type of Connection |

Threaded or Grooved |

Grooved or Flange |

||||||||

|

Material (Body) |

Bronze |

|||||||||

|

Pump Rotor |

Spur or Herringbone Gear |

|||||||||

|

Shaft Type |

Key Shaft or Splined Input Shaft |

|||||||||

|

Material(SHAFT) |

255 Duplex Stainless Steel Shafts |

|||||||||

|

Model |

NF-FP-175 |

NF-FP-201 |

NF-FP-225 |

NF-FP-250 |

NF-FP-350 |

|||||

|

RPM |

1500 |

1800 |

1500 |

1800 |

1500 |

1800 |

1500 |

1800 |

1500 |

1800 |

|

Flow GPM |

135-180 |

185-235 |

158-205 |

202-252 |

180-240 |

240-300 |

185-245 |

250-315 |

280-335 |

375-420 |

|

Pressure psi |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

261-100 |

|

Port Size |

3x3 |

3x3 |

3x3 |

3x3 |

3x3 |

3x3 |

4x4 |

4x4 |

4x4 |

4x4 |

|

Type of Connection |

Grooved or Flange |

|||||||||

|

Material (Body) |

Bronze |

|||||||||

|

Pump Rotor |

Spur or Herringbone Gear |

|||||||||

|

Shaft Type |

Key Shaft or Splined Input Shaft |

|||||||||

|

Material(SHAFT) |

255 Duplex Stainless Steel Shafts |

|||||||||

|

Product Manual |