HFC227ea SYSTEM

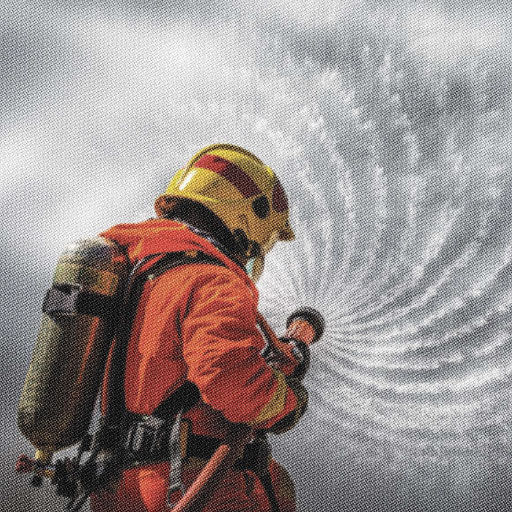

HFC227ea is the safest & effective fire-extinguishing agent used to suppress various types of fires. Most importantly, HFC-227ea does not displace oxygen and therefore is safe for use in occupied spaces without fear of oxygen deprivation.

Latest Impulse Valve Technology adopts efficiency and reliability of reverse acting rupture disc with flexibility of electric activation that make sure no chance for system failure.

• UL & FM approved.

• Clean agent, leaves no residue, hence no cleanup process required, immediate work resuming leads time saving.

• It is a colorless, odorless and electrically non-conductive and non-reactive with other substances.

• Zero ozone depleting

• No global warming effect.

• Safe for total flooding occupied spaces.

• No damage to hazard contents

• No de-composition product.

• No fog and no loss of post-discharge visibility.

• Quick fire suppression

• Container rating DOT 4BW500, TC 4BWM534

• Head valve with impulse technology leads quick opening rather than complicated mechanism in the head valve.

• Complete design, installation, commissioning and maintenance all over the world

• Waterless fire suppression system

• Low refilling, maintenance costs.

• Multiple bigger capacity cylinder configuration enables to propose right amount of gas quantity and reducing cylinder count and thus reduces the project cost also minimal cylinder storage space.

• Supporting for room Integrity test.

• UL listed flow calculation software & providing training.

• 100% design consultancy.

• Easy installation and low installation cost.

• Included on the U.S.EPA significant new alternative policy (SNAP) rules.

• System validation by approved flow calculation software.

FM-200, also known as HFC-227ea, is a clean agent fire suppression system that fulfills the NFPA standard requirements and AHJ (authority having jurisdiction). Clean agent extinguish fire quickly and effectively, are safe in occupied places, and leave no residue. It is the most widely used Halon replacement. System suitable for occupied and unoccupied places.

Safe for occupied spaces, these agents extinguish fire through heat absorption which occurs as they change from a liquid to a vapor during discharge. The gaseous mixture absorbs large amounts of heat and extinguishes fires by cooling the combustion zone.

NAFFCO FM-200 clean agent fire suppression systems are engineered to eliminate fires at the molecular level. Includes Impulse Valve technology for improved design flexibility and longer pipe runs.

The main advantage of NAFFCO FM-200 fire suppression system is that it needs only small amount of extinguishing agent to suppress the fire. The discharge duration within 10 sec., this will prevent ordinary combustible, electrical, and flammable liquid fires from causing severe damage.

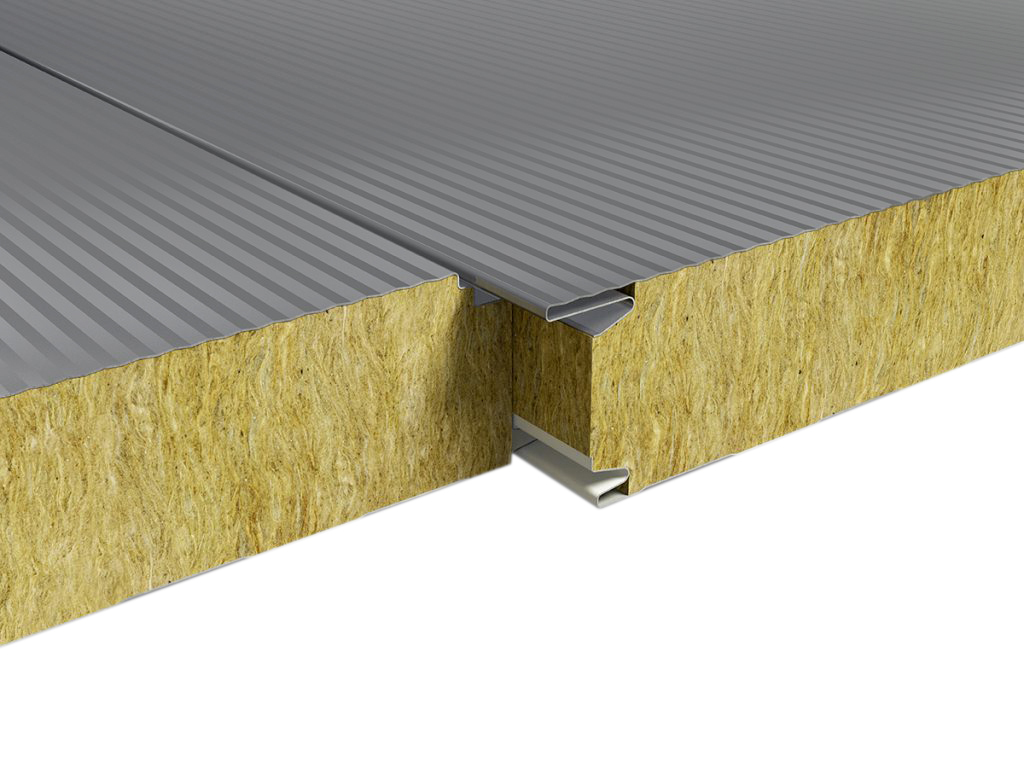

System suitable for Total flooding modular system to protect single room & selector valve system to protect multiple rooms with common bank of cylinders.

System designed to protect special and valuable equipment storage areas.

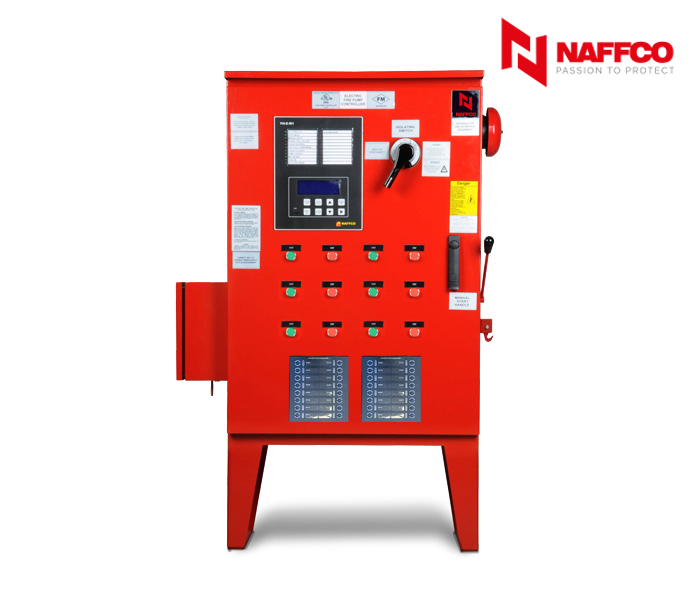

NAFFCO FM-200 system shall include all mechanical & electrical components. Container rating DOT 4BW500, TC 4BWM534. Mechanical components consist of agent storage containers, head valve with pressure gauge, piping, fittings discharge nozzles. Electrical components consist of Extinguishing control panel, detector, agent release switch, abort switch, low pressure switch, discharge pressure switch and notification devices. Our extinguishing control panel capable to release maximum 6 bank of cylinders. Panel shall have feature to interface with auxiliary devices and controls, shut downs, alarm panel interfaces.

Innovative new impulse head valve design consists of ‘Reverse acting rupture disc’ and has no complicated mechanical components leads easy opening and agent discharging.

System can be activated automatic electrically, manually by pressing agent release switch & operating mechanical manual release inbuilt with head valve.

Container head valve open automatically, when container pressure reaches 650 to 750 psi, this fulfill the pressure relief requirements as per DOT regulation.

Cylinder capacity starts from 20 lbs to 1000 lb and based on the agent requires, cylinder can be selected due to cylinder filling flexibility.

APPROVAL:

• NAFFCO FM-200 system comply with NFPA 2001 standard requirements.

• Comply SNAP (significant new alternate policy)

• Approved and tested by UL & FM

• Containers meet with the DOT regulations.

• UL listed flow calculation software