INERT GAS SYSTEM

NAFFCO Inert®... FOUR Gasses, ONE System

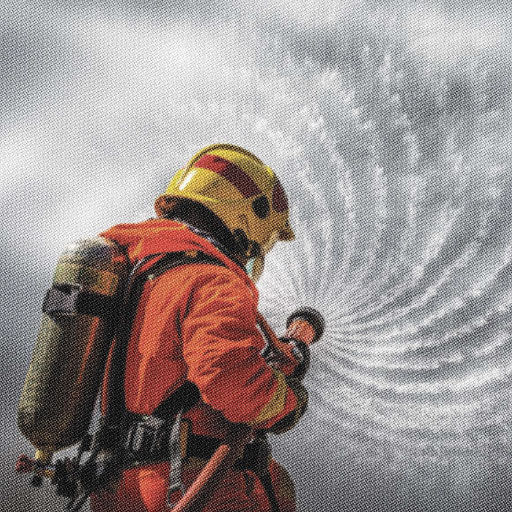

The NAFFCO Inert® Fire Suppression System are safe, clean and a natural way to extinguish fire. NAFFCO Inert® offers IG01, IG100, IG55 and IG541 Gasses with all the components needed to configure a complete system for 200/300 bar inert gas extinguishing agent. Full range of cylinders with 67, 80 and 140 litre capacities.

- Inert gas is clean gas and naturally available in the atmosphere. It is a colorless, odorless and electrically non-conductive and non-reactive with other substances.

- Non-toxic and non-corrosive.

- When discharged into protected hazard, it is clear and does not obscure vision. It leaves no residue and has zero ozone depleting potential and zero global warming potential.

- Inert gas effectively extinguishes all classes of fire (Class A, B, C) except metal fire. Inert gas is a self-propellent and does not require additional propellent.

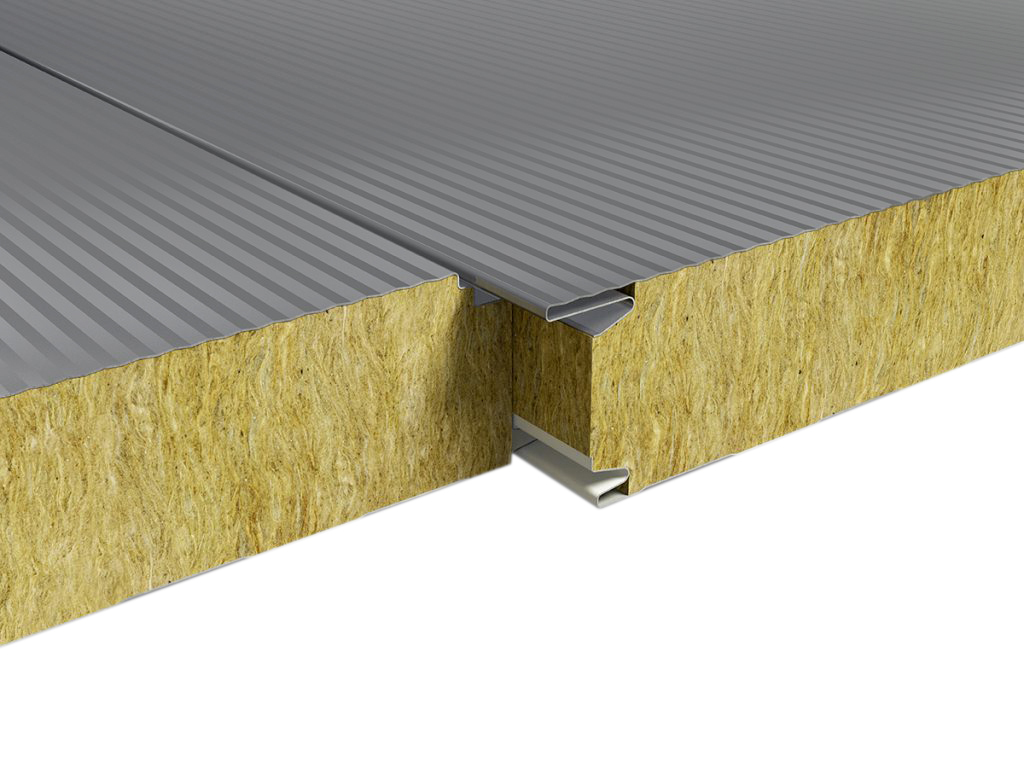

- Cylinders are constructed and marked in accordance to ISO 9809 standard with TPED directive (Pi mark) or accordance to ISO 7285 standard with PESO(CCOE) approved.

- Cylinder capacity available in 67 litre, 80 litre, 140 ltr. Multiple cylinder configuration enables to propose right amount of gas quantity and reducing cylinder count and thus reduces the project cost also minimal cylinder storage space.

- NAFFCO inert gas suppression system available in 200 bar or 300 bar system type. In 300 bar system able to fill more amount agent quantity than 200 bar.

- System regulated pressure shall be 60 bar. Single master cylinders shall open 45 cylinders at a time in second of period.

- NAFFCO inert gas fire suppression system UL listed and FM approved. Engineered system suitable for modular total flooding and for central banking selector valve system to protect common bank of cylinder with multiple area.

- Four types of gases IG-01(100% Argon), IG-55(100% Nitrogen), IG-55(50% Argon +50% Nitrogen), IG-541(NITROGEN 52%, ARGON 40%, CO2 8%) with common components.

- Suitable for occupied and unoccupied hazard. Clean gas, no need of maintenances or cleaning process after discharge. The protected hazard can be occupied /resume activities immediately leads time saving.

- Low refilling cost and reduced maintenance cost. Since our system suitable for protecting multiple hazards by using selector valve with single extinguishing agent, the agent requirement/cylinder number reduced and this also play major role in reducing the project cost.

- Prevents peak pressure at discharge starting. Regulated 60 bar requires low pressure manifolds & pipework to be used – cost saving and easy to install.

Inert gas is a colorless, odorless, electrically non-conductive gas with a density approximately the same as air.

NAFFCO inert gas fire suppression system UL listed and FM approved. Engineered system suitable for modular total flooding and central banking selector valve system to protect common bank of cylinder with multiple area. Four types of gases IG-01(100% Argon), IG-55(100% Nitrogen), IG-55(50% Argon +50% Nitrogen), IG-541(NITROGEN 52%, ARGON 40%, CO2 8%).

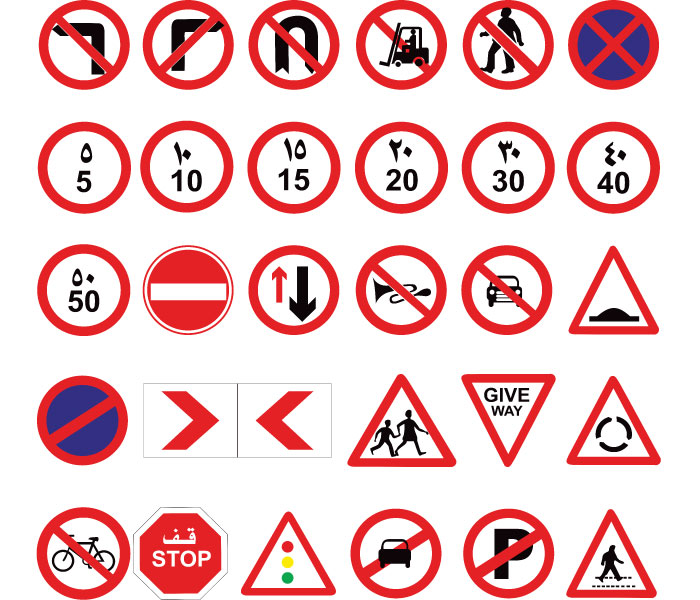

System suitable for Telecommunication facilities, Commercial facilities, medical facilities, Electrical and industrial facilities, Military installation and cultural /historic sites.

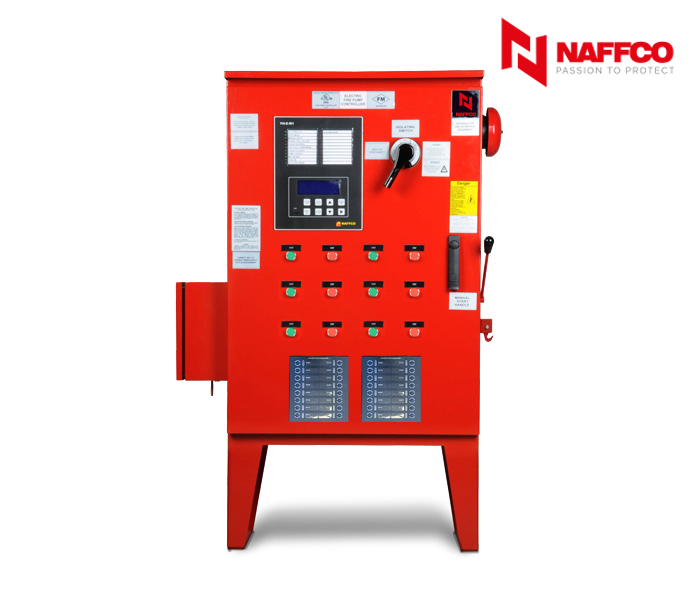

System consists of Cylinder, head valve, pressure regulator, discharge hose with check valve, pilot hose, electric/pneumatic/manual actuators, bleed valve, manifold, manifold safety relief, discharge piping and nozzle. Variable mounting configuration available. Cylinders are constructed and marked in accordance to ISO 9809 standard with TPED directive (Pi mark) or accordance to ISO 7285 standard with PESO(CCOE) approved. Each cylinder delivered protection cap. Cylinder capacity available in 67 litre, 80 litre, 140 ltr.

NAFFCO inert gas suppression system available in 200 bar or 300 bar system type. In 300 bar system able to fill more amount agent quantity than 200 bar. In all the cases the system regulated pressure shall be 60 bar. Single master cylinders shall open 45 cylinders at a time in seconds of period.

Suitable for occupied and unoccupied hazard. Clean gas, no need of maintenances or cleaning process after discharge. The protected hazard can be occupied /resume activities immediately leads time saving. Multiple cylinder configuration enables to propose right amount of gas quantity and reducing cylinder count and thus reduces the project cost. Low refilling cost and reduced maintenance cost.

Since our system suitable for protecting multiple hazards by using selector valve with single extinguishing agent, the agent requirement/cylinder number reduced and this also play major role in reducing the project cost. Regulated 60 bar requires low pressure manifolds & pipework to be used – cost saving and easy to install.

The pressure gauge/low pressure switch assembly can be installed, removed/replaced on a charged container without removing the agent first. System can be released by using either conventional or addressable extinguishing panel as applicable. Wider area coverage of one nozzle is 100 m2 and thus leads the reduce of nozzle count and additional piping requirements. Since our UL listed FM approved local extinguishing panel inbuilt with manual release, it is not necessary to have additional manual release switch and this advantage in reducing the electrical wiring and switch requirements.

Common components for all the four types of Inert gases. Software for all the inert gases have single key and license for long period that enable us to deliver the calculation program result without delay in submission.

APPROVAL:

• NAFFCO Inert gas system comply with NFPA 2001 standard requirements.

• Approved and tested by UL & FM

• Containers meet with the pressure equipment directive.

• UL validated flow calculation software