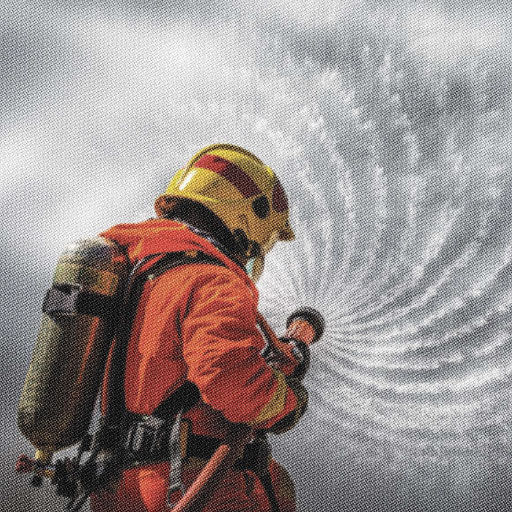

Live Line Insulator Washer

When high voltage working Insulators are contaminated from the environment deposits such as sand, dirt, dust, salt, industrial smoke, cement, etc., it causes leakage of electric current with risk of flashover and thus consequent loss of supply. The best and only solution is to wash these insulators.

TECHNOLOGY

- With the CPSE (Constant Pressure and Separate Engine) system the normal tap water at high pressure is atomized and cleans the surface. The equipment fully complies with new edition of IEEE-957 / 2005 and provides compliance to IEC 61472 with minimum approach distances.

- State-of-art safety Technology implemented to prevent Flashover.

| Model | IW 265 |

| Rotation | 700° |

| Working Height | 67.0m (at nozzle outlet) |

| Rated Washing Point | 65.0m @ 20.00m |

| Horizontal Outreach | 25.0m (at nozzle output @ 45.0m height) |

| Maximum Gradient | 15% as per IEC |

| Maximum Slide Slope | 10% as per IEC |

| Stability Coefficient | >10% as per IEC |

| Water Tank Capacity | 7,000 – 10,000 liters |

| Water Flow | 240 liters/min |

| Water Pressure | 70 bar (Recommended for operation) |

| Mounted on | GVW 48t – 8×8 Heavy Duty |